10% off on Hardrace Products, 17-21 April. (Sale ends on April 21 @11.59pm)

*A $6 monthly account fee applies

(only payable if a balance is owing) See full Ts & Cs

HC800 is a premium Performance Street and Rally brake pad. HC800 has more bite than both NS and B-Spec and has excellent fade resistance. Capable of operating at temperatures up to 800°c, this pad will handle almost all serious braking conditions.

HC800 is a premium Performance Street and Rally brake pad. HC800 has more bite than both NS and B-Spec and has excellent fade resistance. Capable of operating at temperatures up to 800°c, this pad will handle almost all serious braking conditions.

HC800 is a genuine ‘cross over’ pad suitable for both road and track dayse. HC800 is extremely capable in competition environments so use this pad if you are involved in serious track day, rally and hill climb.

Along with temperature capabilities, HC800 is renowned as a ‘drivers pad’ with unmatched driver feel and control.

We have pad compounds to suit all types of driving, so please contract Project Mu Australia to discuss your application requirements.

When brake pads operate at high temperatures, high pressure gases can be created in the pad and can cause a 'gas layer' between the pad and rotor. This can make the driver feel like the brakes have lost performance as the brake pedal feels the same, but the car won't slow down as normal. This phenomenon is known as 'fade'. Project Mu have a unique design to offer the gases an escape route.

When brake pads operate at high temperatures, high pressure gases can be created in the pad and can cause a 'gas layer' between the pad and rotor. This can make the driver feel like the brakes have lost performance as the brake pedal feels the same, but the car won't slow down as normal. This phenomenon is known as 'fade'. Project Mu have a unique design to offer the gases an escape route.

? Rotor slots also assist to provide the same solution.

Brake pads manufactured without a chamfer on the leading edge of the friction material, are more likely to produce unpleasant noise. This noise known as brake squeal is actually a high frequency vibration created by the friction between pad and rotor. The vibration can manifest in caliper, rotor or suspension vibration. This 'problem' is reduced or eliminated by the chamfer on the pad material of selected shapes.

Brake pads manufactured without a chamfer on the leading edge of the friction material, are more likely to produce unpleasant noise. This noise known as brake squeal is actually a high frequency vibration created by the friction between pad and rotor. The vibration can manifest in caliper, rotor or suspension vibration. This 'problem' is reduced or eliminated by the chamfer on the pad material of selected shapes.

? Brake squeal is more likely to occur in some models, and not others. It can also depend on the condition of the car.

Project-Mu brake pads are subjected to heat treatment as part of the manufacturing process. This process 'burns out' unwanted materials in advance, reducing the gases that can cause fade. As a result, Project-Mu brake pads only need light 'bedding in' to match the pad to your rotor surface.

Project-Mu brake pads are subjected to heat treatment as part of the manufacturing process. This process 'burns out' unwanted materials in advance, reducing the gases that can cause fade. As a result, Project-Mu brake pads only need light 'bedding in' to match the pad to your rotor surface.

Brake pads are subjected to huge pressure from caliper pistons in unequal proportions across the pad. Brake pads must remain flat to offer optimal performance so Project-Mu use only the highest grade quality steel at the correct thickness to ensure this stability. Project-Mu pads are up to 20% stronger than some competitors.

Brake pads are subjected to huge pressure from caliper pistons in unequal proportions across the pad. Brake pads must remain flat to offer optimal performance so Project-Mu use only the highest grade quality steel at the correct thickness to ensure this stability. Project-Mu pads are up to 20% stronger than some competitors.

(HCPLUS-F300)

| SKU | HCPLUS-F300 |

| Brand | PROJECT MU |

| Shipping Weight | 50.0000kg |

| Shipping Width | 0.050m |

| Shipping Height | 0.050m |

| Shipping Length | 0.050m |

Help other JDMyard Pty Ltd users shop smarter by writing reviews for products you have purchased.

SKU: HCEP-F304

AU $319.00 GST incl

SKU: RR-1520-10

AU $279.00 GST incl

Welcome to our website. If you continue to browse and use this website, you are agreeing to comply with and be bound by the following terms and conditions of use, which together with our privacy policy govern JDMyard Pty Ltd’s relationship with you in relation to this website. If you disagree with any part of these terms and conditions, please do not use our website.

The term ‘JDMyard Pty Ltd’ or ‘us’ or ‘we’ refers to the owner of the website whose registered office is Unit 25, 317-321 Woodpark Road, SMITHFIELD, NSW, 2164, AU. Our ABN is 53131333312. The term ‘you’ refers to the user or viewer of our website.

The use of this website is subject to the following terms of use:

At Jdmyard Pty Ltd we do things a little differently. For starters, we take a great deal of care when we handle your personal information and we do so in line with the 13 Australian Privacy Principles (APPs) that can be found at the OAIC website (www.oaic.gov.au).

Jdmyard Pty Ltd has developed a simplified and extended policy to help you better understand how your data is stored and used by us, as well as the purpose for which it is used and why. This simplified version will give you a quick snapshot, or if you're up for a thorough read, please view our complete Privacy Policy here.

This simplified Privacy Policy applies to personal information collected by Jdmyard Pty Ltd (jdmyard.neto.com.au).

Both the simplified privacy policy and the extended privacy policy were last updated on 18/08/2015.

At Jdmyard Pty Ltd we accept payments via the following third parties:

Paypal

Afterpay

Braintree

Zip Money

All payment information that is entered on our website is sent to these third parties securely and with industry standard encryption. No payment information is retained on our systems and is all managed by these third parties. Please see their websites above for more information on how they handle your personal and payment information.

Personal information is information that may identify you or by which your identity may be reasonably determined. Such personal information may include your name, address, other contact details, your date of birth, or any other information that may be provided by you in order to access or make use of our services at www.jdmyard.com.au. In this privacy policy, 'personal information' has the same meaning as defined by section 6 of the Privacy Act 1988 ('Privacy Act').

The main way we collect personal information is through you directly or through your authorised representative. That is, when you visit us at www.jdmyard.com.au and submit your personal information or request your personal information to be used (i.e. by subscribing to an email newsletter).

We sometimes collect personal information from a third party or from a publicly available source, but only if:

Your personal information may be collected through the following services that are used on our website:

We only collect personal information for purposes which are directly related to our functions or activities under the Privacy Act, the Freedom of Information Act 1982 (FOI Act), and only when it is necessary for or directly related to such purposes.

We only use personal information for the purposes for which we collected it – purposes which are directly related to one of our functions or activities that on the whole create a better user experience for you at www.jdmyard.com.au.

We do not give personal information about an individual to any government agencies, private sector organisations or anyone else unless one of the following applies:

We take steps to protect the personal information we hold against loss, unauthorised access, use, modification or disclosure, and against other misuse.

When the personal information that we collect is no longer required, we destroy or delete it in a secure manner.

Yes, you can access the personal information that we hold about you, and you can ask us to correct the personal information we hold about you. For more information, see our extended Privacy Policy or alternatively you can contact us directly using the contact details below.

Jdmyard Pty Ltd is bound by the Australian Privacy Principles in the Privacy Act. We care about our users and do everything we can to adhere to the 13 Australian Privacy Principles as per the OAIC guidelines.

For further information contact us at support@jdmyard.com.au or alternatively you can write to us at jdmyard Pty Ltd, 25/317-321 Woodpark Rd Smithfield NSW 2164.

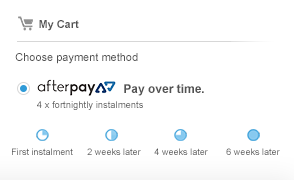

Simple instalment plans available instantly at checkout

Use your existing debit or credit card

No long forms, instant approval online

Pay fortnightly, enjoy your purchase straight away!

All you need is:

1) A payment card; 2) To be over 18 years of age; 3) Resident of country offering Afterpay

To see Afterpay's complete terms, visit https://www.afterpay.com/terms

© 2025 Afterpay